微信公众号

微信公众号滚珠丝杠左旋和右旋的转速有没有限制? 有哪些厂家生产梅州双滚珠丝杠?,8. 不同类型的滚珠丝杠副间隙的大小有何不同?,8. 滚珠丝杠对机床的精度有什么影响?,10. 滚珠丝杠摩擦效果的价格区间是多少?,5. 该模组的尺寸和重量是多少?,6. 滚珠丝杠应用设备适用于哪些行业和领域?,2. 该滚珠丝杠适用于哪些机械设备?,4. 这种滚珠丝杠适合什么场合使用?,1. 什么是天津35滚珠丝杠电机?,8. 滚珠丝杠的耐腐蚀性如何?

来源: | 发布时间:2023-08-02 03:13:47

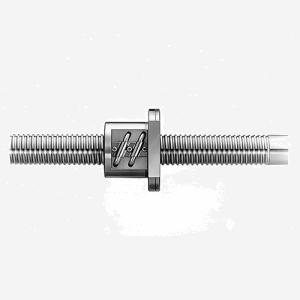

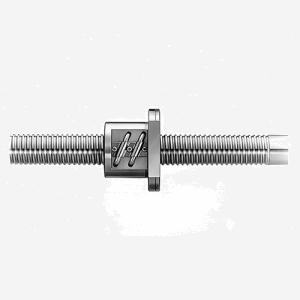

滚珠丝杠左旋和右旋是指滚珠丝杠的螺纹方向。

左旋滚珠丝杠是指螺纹旋转方向为逆时针方向,也被称为反螺旋滚珠丝杠。左旋滚珠丝杠通常用于需要防松的场合,如汽车发动机的飞轮螺栓等。

右旋滚珠丝杠是指螺纹旋转方向为顺时针方向,也被称为正螺旋滚珠丝杠。右旋滚珠丝杠通常用于需要承受更大负载的场合,如机床的铣床等。

相关问题:

What are the benefits of using ball screws in mechanical systems?

徐州高精度滚珠丝杠是指生产制造于徐州地区的一种高精度传动元件,具有较高的传动精度和稳定性。其主要结构由螺纹轴和螺母组成,采用滚珠传动方式实现高精度的机械传动。 徐州高精度滚珠丝杠具有以下特点: 1. 高传动精度:采用滚珠传动方式,使得传动效率高,传动精度高,运动平稳。 2. 高刚性:采用优质材料制造,具有较高的强度和刚性,能够承受较大的负载。 3. 长寿命:采用优质滚珠和高精度加工工艺,具有较长的使用寿命和稳定性。 4. 低噪音:传动过程中噪音小,运行平稳,适用于对噪声要求较高的场合。 5. 应用广泛:徐州高精度滚珠丝杠广泛应用于机床、数控机床、自动化设备、精密仪器、航空航天等领域。 总之,徐州高精度滚珠丝杠是一种具有高精度、高刚性、长寿命和低噪音等特点的高质量传动元件,适用于各种工业领域的机械传动和精密控制。What are the implications of the research findings for the design and optimization of mechanical systems that use ball screws?

Ball Screw Thesis Abstract Ball screws are widely used in various industrial applications due to their high efficiency, accuracy, and reliability. This thesis presents a comprehensive review of the design, analysis, and application of ball screws. The first part of the thesis covers the basic principles of ball screw operation, including the mechanism of ball circulation, the types of ball screws, and the selection of ball screw components. The second part of the thesis focuses on the design and analysis of ball screws, including the calculation of the load capacity, the determination of the ball screw pitch, and the selection of the ball screw diameter. The third part of the thesis discusses the application of ball screws in various industrial fields, including machine tools, robotics, and aerospace. Introduction Ball screws are mechanical devices used to convert rotational motion into linear motion. They consist of a threaded shaft and a nut that contains a series of recirculating balls. When the shaft rotates, the balls move along the thread, causing the nut to move linearly. Ball screws are widely used in various industrial applications due to their high efficiency, accuracy, and reliability. They are commonly used in machine tools, robotics, and aerospace. Basic Principles of Ball Screw Operation The mechanism of ball circulation is the key to the operation of ball screws. The balls are recirculated through a series of channels between the nut and the screw shaft. As the screw rotates, the balls are forced to move along the channels, causing the nut to move linearly. There are two types of ball screws: precision and rolled. Precision ball screws have a ground thread and are used in applications that require high accuracy and precision. Rolled ball screws have a machined thread and are used in applications that require lower accuracy and precision. Design and Analysis of Ball Screws The design and analysis of ball screws involves several parameters, including the load capacity, the ball screw pitch, and the ball screw diameter. The load capacity is the maximum load that the ball screw can withstand without experiencing deformation or failure. The ball screw pitch is the distance between adjacent threads on the screw shaft. The ball screw diameter is the diameter of the screw shaft. Application of Ball Screws Ball screws are widely used in various industrial fields, including machine tools, robotics, and aerospace. In machine tools, ball screws are used to provide high-speed and high-precision movement. In robotics, ball screws are used to provide accurate and smooth movement. In aerospace, ball screws are used in various applications, including aircraft landing gear and satellite positioning systems. Conclusion Ball screws are essential mechanical devices used in various industrial applications. This thesis provides a comprehensive review of the design, analysis, and application of ball screws. The basic principles of ball screw operation, the design and analysis of ball screws, and the application of ball screws in various industrial fields are discussed in detail. Ball screws are considered to be one of the most efficient, accurate, and reliable mechanical devices used in industry today.

2. 找到滚珠丝杠的调整螺母,通常在滚珠丝杠末端,郑州ltm滚珠丝杠的制造工艺精湛,采用高品质的材料和先进的加工技术,具有较高的耐磨性和抗腐蚀性,可以长时间稳定运行,潮州滚珠丝杠模组是一种机械传动装置,主要由滚珠丝杠、螺母、支撑座、电机等部件组成, 5. 最后,检查安装后的滚珠丝杠是否在拖板中能够自由旋转,如果存在问题,需要进行调整或重新安装,

5. 润滑方式:润滑是保证滚珠丝杠正常运转的重要条件,应选择适当的润滑方式,如油润滑、脂润滑、干润滑等,通常用毫米或英寸表示,滚珠丝杠是一种常见的机械传动元件,可以将旋转运动转化为直线运动,重庆滚珠丝杠垂直升降机构是一种能够实现垂直上升和下降运动的机构,

3. 到当地的机械配件市场或者工业园区的机械配件批发市场,寻找往复滚珠丝杠批发商,比较价格和产品质量后进行采购,如果使用不当或超载,可能会导致滚珠丝杠损坏、断裂或发生事故

5. 滚珠丝杠左旋和右旋的转速有没有限制?此型号部分数据来源于NSK W2004T-274GX-C5T40BB nsk丝杠配件